Smaller nuclear energy technology could play a role in bolstering the U.S. nuclear industry due to potential economic advantages over traditional plants, a UW-Madison expert says.

That’s according to Benjamin Lindley, assistant professor of nuclear engineering and engineering physics at the university. He spoke yesterday during a seminar focused on small modular reactors and microreactors, hosted by the Wisconsin Energy Institute.

He noted about 90 nuclear reactors are operating in the United States, and several had been closed down in recent years due to economic reasons, such as cheaper gas and variability in energy prices. But over just the past two years or so, other factors have driven “a dramatic reversal of fortunes” for nuclear, as data centers drive higher electricity demand amid higher gas prices linked to the war in Ukraine.

“So now, there are currently plans to restart at least two of the ones that shut down … and the current plants are also thinking about how they drive even more power out of their existing plants,” he said, noting that will require substantial investments in these facilities.

Despite this turnaround, projections for U.S. nuclear energy production are “basically flat” through 2050 based on figures from the U.S. Energy Information Administration Lindley referenced.

Because building new traditional nuclear reactors is so expensive and difficult — Lindley described them as “megaprojects” that nearly always go over budget and take longer than initially planned — efforts are now being made to miniaturize nuclear energy production to improve the economics. He noted tech giants Amazon and Google are putting money into developing advanced nuclear technologies.

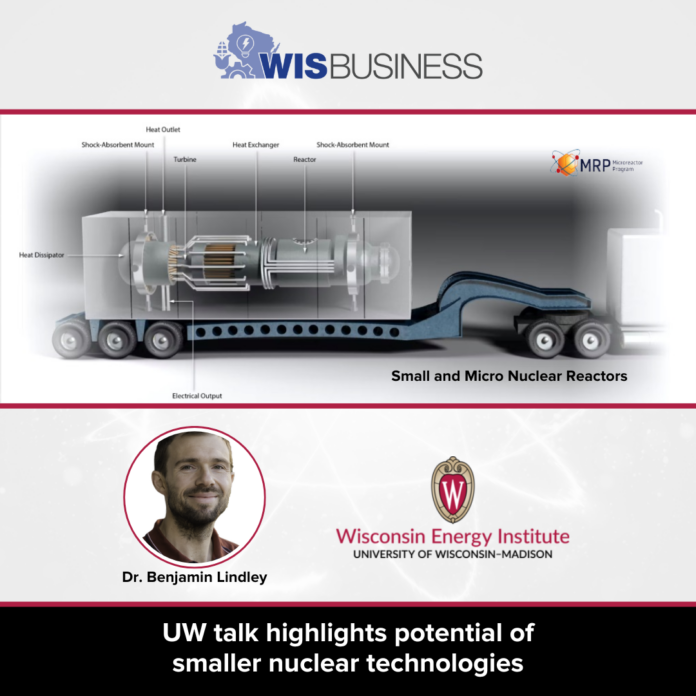

One route to doing so involves creating small modular reactors, or SMRs. This concept leverages the efficiency and reproducibility of factory-based manufacturing, as most parts of these installations would be built elsewhere and then shipped to the desired location. Doing as little work as possible on-site would help reduce related costs, according to Lindley.

“Standardization, have one design and stick to it. Build it over and over again, exactly the same with the same supply chain, the same people and same manufacturing process,” he said. “That is known to work, right, in general. If you standardize something, you bring the cost down … It’s pretty much indisputable that this is a good idea.”

He referenced an Oregon company called NuScale, which signed an agreement with La Crosse’s Dairyland Power Cooperative to explore possible uses of the technology. The presentation noted the company convinced U.S. nuclear regulators that their approach doesn’t need as large of an “emergency zone,” reducing logistical concerns with the emerging technology.

Meanwhile, even smaller nuclear units called “microreactors” are being explored as another alternative. Also envisioned as a single structure that could be made in a factory and transported elsewhere, these could be used as a resilient power source for remote communities with extreme environmental hazards.

In parts of northern Canada or Alaska, where a power outage could be fatal during the cold winter months, these microreactors could be used as an alternative to the costly process of shipping diesel fuel, Lindley explained. He said they could also power space missions or military bases, adding he believes the U.S. military is close to testing such a reactor.

“The military is really interested in microreactors in order to transport them to forward bases, and the reason for that is because fuel supply lines are a major source of casualties for the army,” he said. “So if you could have a nuclear reactor and you can operate it where soldiers are, then it means that you don’t have to ship as much diesel around, which reduces casualties.”

Watch the video.