A manure digester at Crave Brothers Farm in Waterloo produces electricity for the township and bedding for the cattle. It also reduces methane emissions.

Tom Crave says his family’s dairy farm is leading the way in sustainability by operating at 100 percent green power. Since adding a manure digester in 2006, the 2,200-cow farm is producing enough electricity for farm operations, Crave Brothers Farmstead Cheese and the roughly 300 homes in the township.

Crave, the president-emeritus of the Dairy Business Association, said he thinks every farm has a role in protecting the environment.

“They have to look in the mirror and realize it,” he said. “We all can improve on being more environmentally friendly or sustainable. We’ve decided to go this way.”

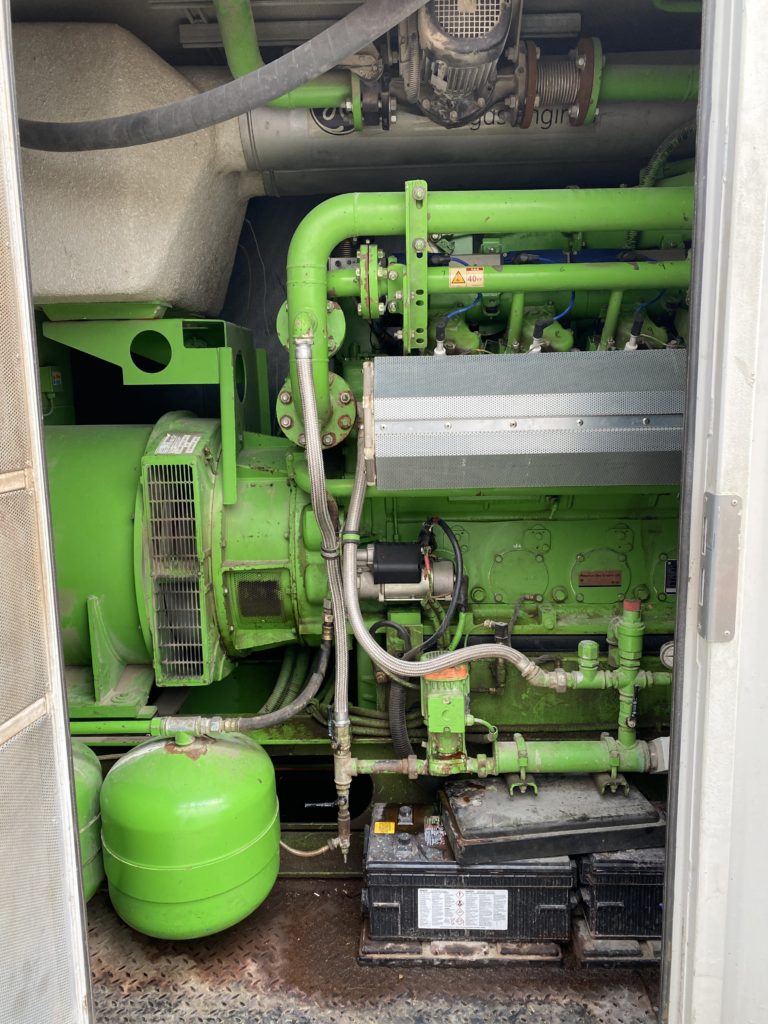

All the manure from the 3,600 head of cattle on-site goes into two 750,000-gallon tanks. Those tanks imitate a cow’s stomach at 101 degrees. At that temperature, it further digests and ferments the animal waste. In that process, methane gas rises to the top of the tanks like a big bubble or balloon. It’s taken off of the top and burned to run a generator that makes electricity. The exhaust heats those tanks.

But the manure digester doesn’t get rid of the manure. The soggy, leftover waste is squeezed to produce a solid and a liquid byproduct. The solid byproduct is dried to resemble peat moss. It’s soft and sweet-smelling and used as animal bedding.

The liquid is pumped into a lagoon on the farm and used as organic fertilizer on the farm’s 3,000 acres.

Bedding is the solid byproduct of the manure digester. Image by Stephanie Hoff, April 2, 2021

Clean Fuel Crave sign on the manure digester building. Image by Stephanie Hoff, April 2, 2021

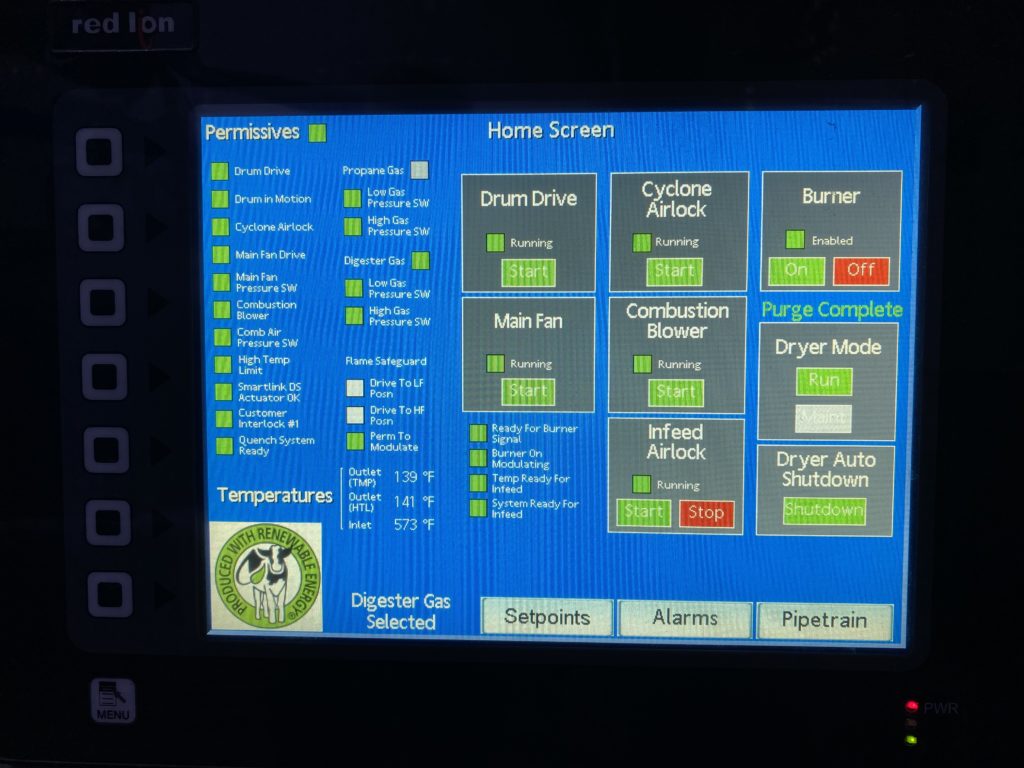

The manure digester is run by a computer. Image by Stephanie Hoff, April 2, 2021

The solid manure byproduct is dried to become bedding. Image by Stephanie Hoff, April 2, 2021

The engine running the manure digester. Image by Stephanie Hoff, April 2, 2021

“One of the benefits that we get from the digester is not only the bedding and separated manure, but we eliminate about 90 percent of the odor in the manure,” Crave told WisBusiness.com. “Can we put a price tag on that? Not directly. But it makes us better stewards or neighbors … Our friends in town, they don’t smell it.”

Originally, the Craves partnered with an electrical contractor from Milwaukee, but for the past 10 years, the farm has been operating the digesters on its own. The farm has a power purchase agreement with WE Energies.

“I would say economically, we’ll call it break-even. It costs a tremendous amount of money to build and operate,” Crave said. “We offset it by two things: we sell the electricity and we do not have to import or buy bedding or our cattle.”

Crave Brothers Farm is a concentrated animal feeding operation, otherwise known as a CAFO. To be a CAFO, farms have 1,000 animal units or more. About 700 cows is equal to 1,000 animal units.

As a CAFO, Crave Brothers Farm has a permit from the DNR to discharge manure under certain conditions. One of those conditions is having a nutrient management plan. The plan dictates that Crave test their soil and liquid manure for nutrients. That information, in addition to the location of waterways and the type of crops planted, helps the farm apply liquid manure to the right locations in the right amount at the right time.

“One of the myths about CAFOs is that they’re big polluters, and it’s actually just the opposite. CAFOs are large farms that have nutrient management plans and do a better job distributing their organic fertilizer than a lot of other farms because we have the system, we have the book on doing it. We can’t spread anything without it being in the book.”

He said any crop farmer should look into a nutrient management plan, which targets fertilizer application to prevent over-fertilizing, saving farmers money. He argued if everyone had a nutrient management plan, it would make a “dramatic difference” in soil and well contamination happening around the state.

Crave explained that to him, a sustainable operation means taking care of crops and cattle in an environmentally friendly way while being able to sustain the business — finding a “happy medium” between caring for the Earth and caring for the business so eco-friendly initiatives can continue.

“Everybody wants a clean environment. We can make a clean environment and have a healthy agricultural economy here in the state,” he said. “Overall, production agriculture does a good job taking care of the environment, and there is room for improvement — there always is. This topic isn’t going to go away. As we find better ways to take care of the environment, we’ll adopt them.”

-By Stephanie Hoff

WisBusiness.com